Aircraft Birch Plywood

Thomes Ltd. is the sole Canadian importer of KOSKIPLY, also known as aircraft plywood or craft plywood. This thin craft plywood material is made by a leading forest products manufacturer in Finland.

Our aircraft plywood consists of ultra-thin birch veneers that meet Germanischer Lloyd (GL) standards. Many applications use this material because of the excellent quality features that it offers. Some of these features include extreme strength, lightness, ease of working, and flexibility.

Aircraft Grade Plywood from Thomes Ltd.

Thomes offers high-quality aircraft plywood with the following specifications:

- Thicknesses ranging from 0.4mm (3 ply) to 10mm (20 ply)

- Phenolic resin glue that makes it both weather and boil-proof

- Standard sheet size carried in inventory is 50″ by 50″

- Other sizes available include 48″ x 48″, 60″ x 60″, as well as custom orders

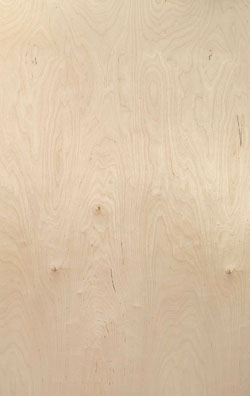

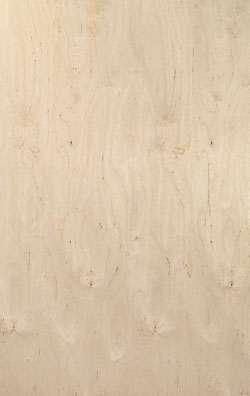

Face Grades

Aircraft plywood is the highest grade of durable plywood. This material is commonly made from birch, spruce, and/or mahogany with adhesives that are resistant to humidity and heat. Aircraft construction has used this material since World War II because of its strength and reliability. In addition to aircraft, this type of plywood is also commonly used in the manufacturing of boats, instruments, furniture, and more.

In the Aircraft: Applications of Aircraft Birch Plywood

Aircraft plywood was commonly used in the manufacture of the first propellers used in airplanes, hence its name. Other aircraft applications of this material include:

- Gussets for wing ribs

- Floorboards

- Instrument panel construction

- Reinforcement plates for wing spars

- Leading edges of wings

- Skins for entire wing panels

Other Applications of Aircraft Birch Plywood

In addition to aircraft applications, the many desirable characteristics of aircraft plywood make it and ideal choice for various other applications, including:

- Boats, including the manufacture of boat hulls

- Furniture components

- Model airplanes and boats

- Musical instruments such as drums and guitars

- Toys, including boomerangs and dollhouses

- Packaging such as cigar boxes, liqueur and wine cases, commemorative gift packaging, Christmas ornaments, and boxes of chocolate and caviar

- Laser-cut art projects that display the wood layers and the visible relief and contours

- Laser-cut gifts, special invitations, and topography and relief maps

- Nearly anything else you can create with wood!

Types of Aircraft Plywood

The production process for aircraft plywood resembles that of regular plywood. However, the wood and resins used are of a higher quality. Most aircraft plywood consists of either birch or African mahogany, due to these woods’ increased hardness, tensile strength, and smoother grain structure. Douglas fir wood, a common standard plywood species, has a total tensile strength of 2.3 GPa, while birch wood has a tensile strength of 2.60 GPa, giving it 15% more strength than standard plywood. Unlike other woods, birch and mahogany are normally devoid of voids or pockets, making them the ideal species for a strong and clean product.

Manufacturers use thermosetting, synthetic resin adhesives when producing aircraft plywood. Aircraft plywood must also meet stricter quality requirements compared to industrial plywood. One specification that aircraft-grade plywood must meet is MIL-P-6070B, which requires plywood to undergo testing for:

- The general condition of the board

- Thickness deviations

- Moisture content

- The tensile strength of the wood

- Bending

- Gluing strength

- Immersion

- Boiling

Why Choose Aircraft Grade Plywood?

Although aircraft plywood is somewhat similar to traditional plywood, it features qualities that emphasize performance over aesthetics. This wood has a naturally appealing appearance due to the species of wood it requires for optimal performance. Aircraft plywood comes in boards that can be as thin as 0.40 mm. Applications often use standard plywood instead of aircraft plywood because of its more affordable cost, but aircraft plywood is often better to use if your budget allows for it.

Aircraft plywood is made from only a limited number of wood species, including birch or mahogany for the face veneers, with basswood, poplar, or maple within its core. However, the primary element of this plywood that allows for its peak performance is the adhesive that bonds the wood pieces together. This adhesive usually consists of phenol-phenolic glue. This is critical as MIL-P-6070B requires adhesives to be both fireproof and waterproof. The bonding process uses a hot press before drying the adhesive with a kiln.

The end product then needs to pass a test that’s similar to the WBP certification process for regular plywood. The test involves boiling the sample for 20 minutes, after which testers perform a peel test. During the peel test, the wood veneer fibers need to pull apart before the adhesive.

Aircraft Grade Plywood from Thomes Ltd.

Looking for top-quality aircraft birch plywood for your application? Thomes can provide superior aircraft plywood in a range of thicknesses and custom sizes to your specific requirements.

For more information about our aircraft birch plywood and other products, contact us today.

CONTACT US TODAY

Our MISSION is Supply Chain Oriented, to find you the best option to solve your production requirements.

- 1st to Market In Plywood

- 50+ Years Experience

- 2 Way Feedback with Mills

THOMES NORTH AMERICA

200 King Street East, Suite 201Bowmanville, ON, Canada. L1C 1P3

www.thomesnorthamerica.com

sales@thomesnorthamerica.com

Tel: +1 905 623 9888

Fax: +1 905 623 7444

NOTE: We are not a retail supplier.

For retail locations, tell us your location, and what you are interested in buying. What quantity, and we will put you in contact with our partners near you. Send your email to: