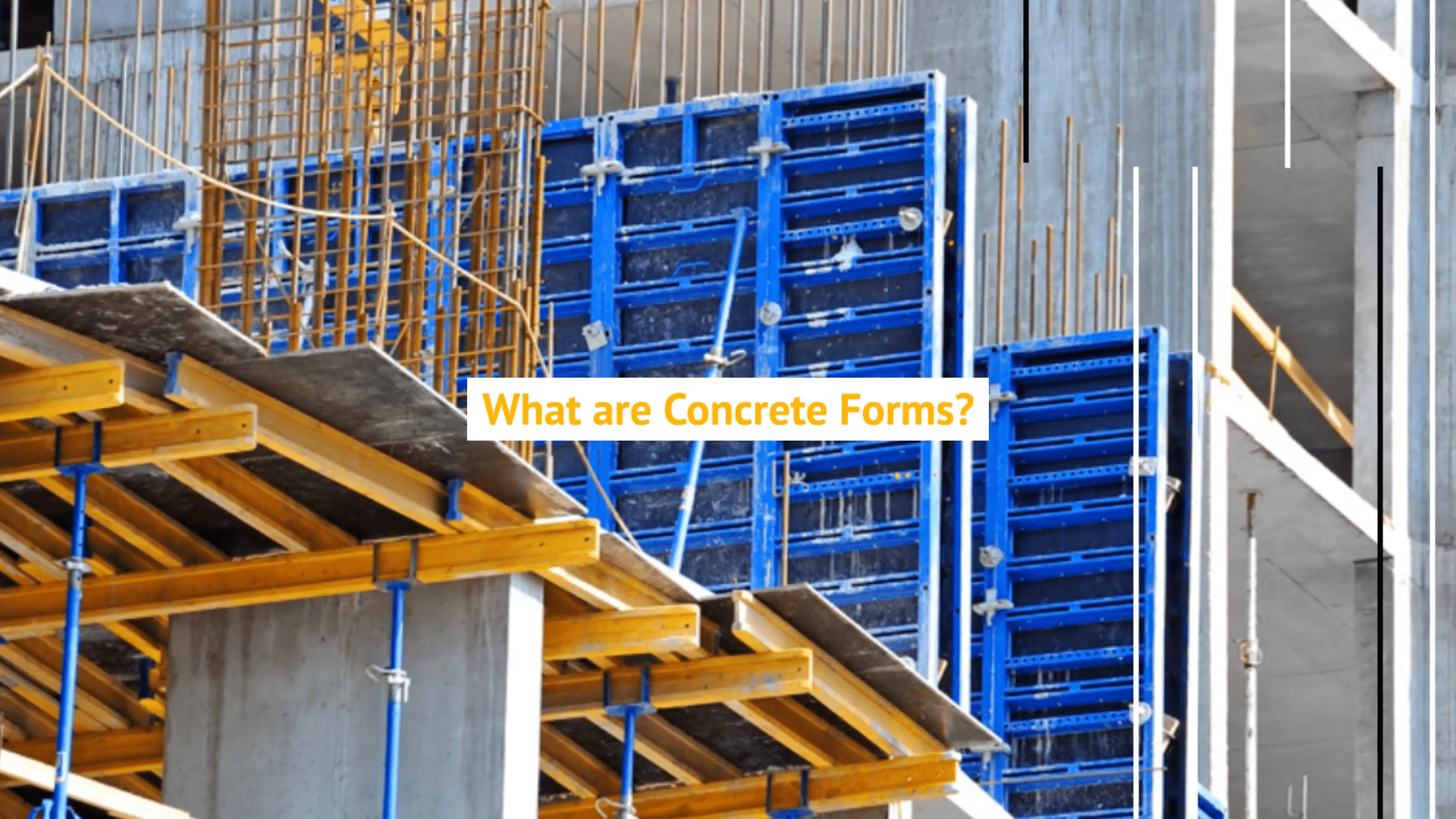

Concrete forms provide a solid barrier for holding concrete in a particular form until it hardens. When planning a concrete project, it’s important to choose the right type of concrete forming materials to ensure optimal results. The type of concrete formwork you choose will have a significant impact on the success of your project.

What are Concrete Forms?

Concrete formwork is an effective way to ensure that poured concrete takes the intended shape and sets properly. The concrete forming materials can also achieve the desired finish along the form’s surface. Concrete forms, especially concrete form boards, also maintain proper alignment for long, continuous pours.

As most concrete pours occur outdoors, concrete forming materials must be resistant to warping under the sun or due to temperature fluctuations. Concrete forms must also withstand the pressures exerted by both the concrete itself and the application of tools, sometimes including heavy machinery designed to pack, spread, or vibrate the concrete before it sets.

To ensure easy, damage-free removal of the concrete formwork, it’s essential to select the right type of wood for concrete forms. Generally, lighter materials are preferable.

Benefits of Baltic Birch Plywood Concrete Forms

Wood concrete forms must fulfill several key requirements to ensure they set properly and are easily removed. Requirements include the following:

- Enough strength to withstand heavy loads without shifting

- A stick-free surface

- Lightweight and easy to work with

- Long-term durability and high reusability

- Weatherproof and resistant to rot

- Easy to clean

Phenolic-coated Baltic birch plywood fulfills all of the above mentioned requirements. Commonly used in cabinetry or flooring, phenolic-coated birch is the most effective type of wood for concrete forms, and concrete formwork experts rely on it to ensure defect-free removals from set concrete.

Other wood forms are usually textured, which causes the concrete to stick and increases the risk of damage. Only phenolic-coated Baltic plywood creates a quality concrete finish where it contacts the form. Baltic birch plywood is durable enough for repeated long-term use and resists rot even in wet or humid climates.

Baltic birch can also be a much more affordable option, especially with wholesale distributor pricing. Because Baltic birch plywood is often used for cabinetry or high-traffic flooring, where aesthetics are important, carpenters and flooring companies often require Grade A quality materials. Concrete forms are purely functional, so a lower grade is perfectly acceptable.

Our customers in the concrete wholesaling industry also find Baltic birch easy to market straight to concrete professionals, who often fabricate their own concrete forms. Because it’s lightweight, Baltic birch is highly workable, and it holds its shape easily even while maintaining strength.

Concrete Forms by Thomes North America

Wood concrete forms made from phenolic-coated Baltic birch plywood are the optimal solution for any concrete formwork. As the most dependable supplier of Baltic birch plywood for industrial or commercial use, Thomes North America sources our Baltic birch from Finland and Latvia wholesalers. Because we’re one of North America’s largest importers of Baltic birch plywood, we offer competitive pricing for concrete form manufacturers and wholesale centers.

We can also provide direct mill shipments on high-volume orders. For more information on using phenolic-coated Baltic birch plywood in concrete forms, contact us, and speak with an experienced team member.