What is Baltic Birch Plywood?

What is Baltic Birch Plywood

Thomes is one of North America’s largest suppliers and importers of Baltic birch plywood. With over 50 years of industry experience, we provide high-quality lumber from Latvia and Finland, allowing manufacturers to acquire high-quality plywood at a lower cost, with more selection and availability than our competitors.

Baltic birch plywood offers extreme durability and versatility and is a preferred choice of material for many industries and applications. For wholesale customers looking to buy Baltic birch plywood, we offer direct mill shipments for large orders and warehouse deliveries for Canada and U.S.-based plywood distributors.

Overview of Baltic Birch Plywood

Baltic birch plywood refers to any type of birch sourced from the Baltic states. Thomes sources our Baltic birch specifically from Finland and Latvia.

Baltic birch plywood contains a cross-banded all-birch veneer core, laminated with exterior-grade glue. This type of plywood has a thicker face veneer and offers superior stability compared to traditional cabinet-grade plywood. Baltic birch has exceptional screw-holding strength and easy machinability, making it far superior to other types of plywood. For these reasons, Baltic birch is the preferred plywood type for crafting finger or dovetail joints in woodworking projects.

Grades of Baltic Birch Plywood

There are several grades of Baltic birch plywood:

Grade B

This one-piece face is typically light and uniform in color, with the surface sanded to create a natural finish. Minor brown streaks and occasional small pin knots may be acceptable, but this plywood grade should not have mineral streaks, voids, or patches. During summers, availability tends to be limited.

Grade BB

This one-piece face is usually light and consistently colored. Slight discoloration, mineral streaking, and pin knots are permitted. Before gluing, defects and open knots in BB face veneers must be removed and replaced with round or oval veneer patches that are the same color as the face veneer. The surface is sanded to create a smooth finish.

Grade CP

The one-piece face has a sanded surface and resembles grade BB plywood but may contain more streaking and minimal defects. Hairline splits of less than 0.5 mm are allowed, and the round or oval patches can match the color of the base face veneer, although it is not required. CP-grade plywood typically contains more patches per face compared to BB-grade plywood.

Types of Baltic Birch Plywood

Listed below are the types of available Baltic Birch Plywood from Thomes Ltd.

Veneer Core Plywood

In veneer core plywood, all the plies are oriented with the plane parallel to the panel’s surface. The direction of the grain in adjacent plies typically forms a right angle, with the inner and outer plies placed symmetrically on either side of a central core or ply. Lathes produce standard plywood veneer, peeling the log the same way a blade sharpens a pencil. A synthetic resin adhesive gets applied to the veneer before assembly, with the grain of each sheet at a 90° angle to the adjacent veneer plywood.

Film-Faced Plywood / Phenolic Plywood

Phenolic plywood is an engineered material created by combining and adhering various pieces of birch wood, such as sawdust, wood fibers, scrap wood, and genuine wood. Typically, 13 to 15 layers of these wood pieces create a 3/4-inch sheet. Phenolic plywood is a widely accepted material commonly used in residential and commercial construction.

When phenolic plywood is coated on both sides with treated resin, it becomes film-faced birch plywood. This film makes the plywood waterproof and wear-resistant, suitable for outdoor applications, such as outdoor playground equipment and furniture. The film can extend the service life of the plywood core.

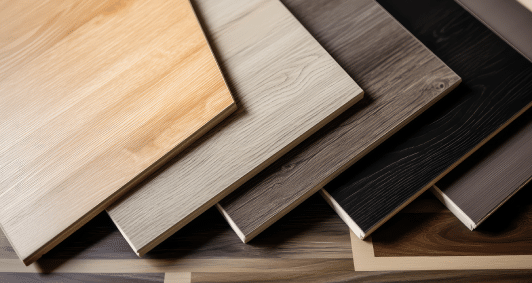

Melamine Coated Plywood

While melamine is a form of laminate, not all laminates are melamine-based. Melamine-coated plywood is created by applying a set amount of pressure per square inch to the laminate, achieved by molding a combination of formaldehyde and melamine into a durable plastic sheet. The amount of pressure applied determines the laminate’s classification.

Melamine-coated plywood is resistant to fire, heat, stains, scratching, and moisture. It’s a common material selected for particleboard and medium-density fiberboard (MDF) applications.

Applications for Baltic Birch Plywood

The durability, strength, moisture resistance, and ease of customization make Baltic birch plywood a good material choice for a wide variety of applications, some of which include but are not limited to:

Automotive

CNC cut-out parts and custom full-size panels create anti-slip flooring, seat backs, door panels, and wall cladding. The most common application is vehicle flooring for commercial vehicle flooring, trailers, and semi-trucks.

Construction

Baltic birch plywood can be used to create concrete forms to ensure that poured concrete sets properly and takes on the desired shape. It can also maintain proper alignment for lengthy continuous pours and achieve the intended finish along the form's surface. Wall paneling is another construction industry application that benefits from using Baltic birch plywood.

Aerospace

Aircraft plywood consists of ultra-thin birch veneers, making it lightweight and flexible yet extremely strong. The material can be painted, finished, and stained like wood, and the veneer face plies are defect-free, making it an ideal solution for airplane paneling.

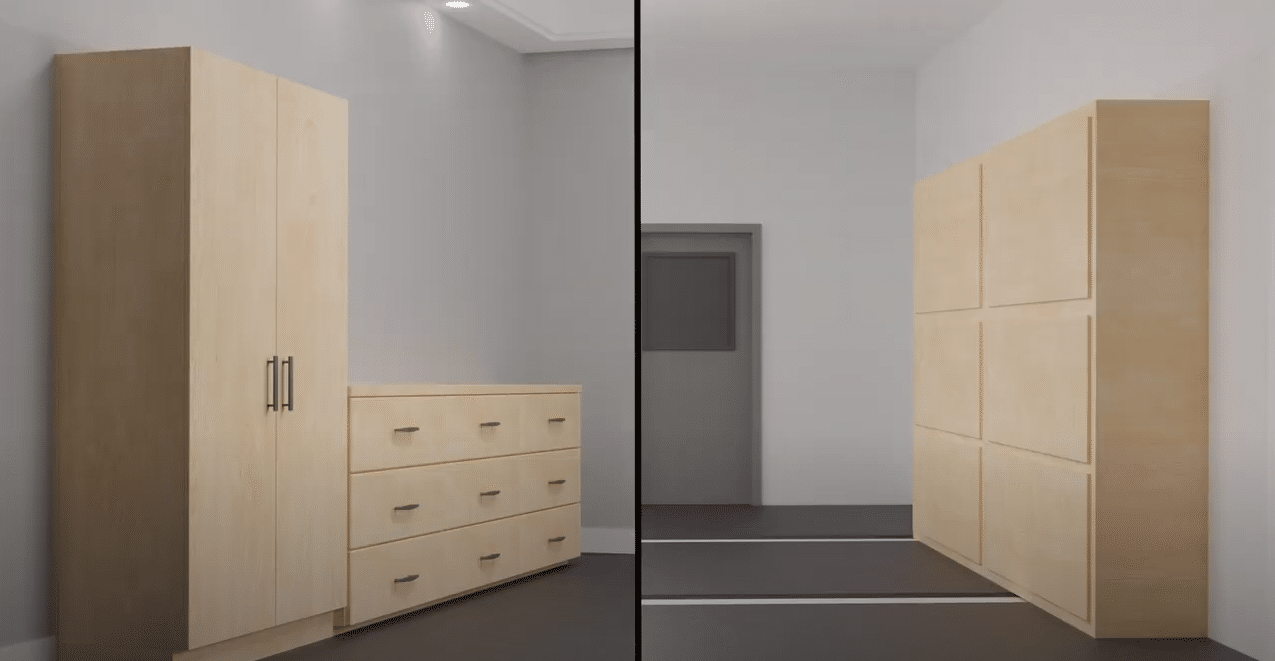

Furniture

Baltic birch plywood is ideal for making furniture, such as cupboards, tables, stools, cabinets, and chairs. Its long lifespan and dimensional stability make it a preferred choice in furniture used for home, school, office, and retail settings.

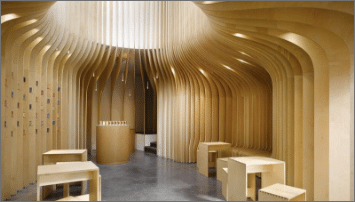

Architecture

Engineered plywood proves beneficial in structural and building elements in airports, outdoor libraries, museums, and hotel lobbies. The birch creates a light red-brown finish, offering few impurities in the curved or straight grain, making it a perfect solution for architectural applications.

Hobbyist/Crafting

Baltic birch plywood is much sturdier than balsa wood, making it a good material choice for crafters, artists, and hobbyists. Baltic birch is also the preferred option for engraving and laser cutting, offering durability, an aesthetically pleasing fine-grain appearance, uniform light color, and affordability compared to other materials.

Baltic Birch FAQs

With over 50 years of experience, Thomes Ltd. North America provides high-strength, versatile Baltic Birch for a variety of vehicle, aircraft, trailer, furniture, and other applications.

Below are answers to our most Frequently Asked Questions (FAQs) about Baltic Birch. If you do not see your question addressed, please contact our knowledgeable customer support team for more information.

What Makes Baltic Birch different from regular birch plywood?

Several characteristics set Baltic Birch apart:

- Hardness. European birch is considerably harder with a Janka hardness rating between 1200 and 1350 ibf. In contrast, poplar has a Janka hardness rating of approximately 540 lbf. Because it is harder, birch plywood is more durable than alternatives.

- Layers. Baltic Birch plywood has twice as many layers (plies) as standard birch plywood. A ¾ in. (18mm) sheet of Baltic Birch plywood consists of 13 equal layers, whereas standard birch plywood typically only contains between five and seven layers.

- Material thickness. Baltic Birch plywood face plies are 1.5 mm thick, which means there is more material for sanding compared to other options.

- Reliability. Baltic Birch plywood is void-free with a core that is significantly harder than standard birch plywood. This gives it a consistent thickness for optimal wood grip when securing screws in place.

- Stability. Baltic Birch plywood is ideal for heavy-duty and load-bearing applications because it has greater strength and stability than standard birch plywood. What’s more, each layer consists of birch instead of other core types, such as particle board or medium-density fiberboard (MDF).

- Versatility. Baltic Birch is tough enough for use in truck and trailer beds, yet highly aesthetic for use in furniture.

Is Baltic Birch Waterproof?

While it is not inherently waterproof, Baltic Birch plywood is exceptionally water resistant due to the glue with which it is constructed. The birch veneer layers are bonded using a waterproof adhesive that gives Baltic Birch plywood the ability to withstand exposure to humidity and moisture.

Manufacturers often choose Baltic Birch plywood over standard birch plywood for use in applications that require reliable water resistance, such as outdoor, marine, and cabinetry projects.

Why are Baltic Birch sheets offered in 5 ft. x 5 ft. & 4 ft. x 8 ft. sizes?

Baltic Birch plywood sheets are usually manufactured in 5 ft. x 5 ft. (1525 mm x 1525 mm) or 4 ft. x 8 ft. (1220 mm x 2440 mm) sheets to meet specifications for European cabinetry. An interior glue is used on the 5 ft. x 5 ft. sheets, and the 4 ft. x 8 ft. sheets are typically constructed using a moisture-resistant phenolic resin.

Is Baltic Birch a good material for truck flooring?

Yes. Specifically, 5 ft. x 5 ft. sheets of Baltic Birch plywood exhibit exceptional moisture-resistant characteristics. It is also a preferred material choice for commercial vehicles because it can hold up to exposure to road sand, salt, and grit.

Film Wire and Heksa Baltic Birch plywood feature an anti-slip film coating made of high-density paper impregnated with a phenol-formaldehyde resin. One side of the plywood has a film face with a hexagonal or wire mesh surface pattern, and the other side has a smooth film overlay for optimal slippage protection.

The film-faced material is ideal for truck flooring, as it is not damaged by exposure to various chemical and environmental conditions. Its multilayer panel structure also provides superior strength for wear resistance and bearing loads.

Commercial auto makers prefer film-faced Baltic birch plywood for truck flooring for several reasons:

- Anti-slip surface pattern.

- Ease of cleaning.

- Exceptional wear and slip resistance.

- High load-bearing capacity.

- Lightweight material.

- Minimum rolling wear.

- Safety of cargo shipments during transport.

Is Phenolic Glue Toxic or Dangerous?

No. Phenolic glue is safe for the environment and human health. The California Air Resources Board (CARB) identifies phenolic glue as an ultra-low-emitting formaldehyde (ULEF).

Paper overlays or veneers on 4 ft. x 8 ft. and 5 ft.’ x 5 ft. Baltic Birch plywood are impregnated with phenolic glues. The material exposed to the phenolic glue is classified as a No Added Urea Formaldehyde (NAUF), which meets the requirements for EN 314-2. Baltic Birch plywood (i.e., constructed with phenol formaldehyde glue, exhibiting low levels of formaldehyde emissions).

All materials sourced through Thomes Ltd. North America are TSCA 6 and CARB2 certified.

Is Baltic Birch compatible with CNC and laser cutting?

Yes. Baltic Birch plywood is one of the few wood substrates available in large enough sheets with a thickness that exhibits consistent density for laser cutting. In addition, its veneers are thicker than those in standard birch plywood, making it a better choice for customization and sanding without compromising structural reliability.

Thomes Ltd. North America recommends using a 5 ft. x 5 ft. sheet of Baltic Birch plywood for laser cutting, as the urea-formaldehyde glues bond the plies together well. An interior laser-grade aircraft plywood, constructed using a melamine-formaldehyde glue, can also be used with laser cutting and CNC machinery.

Baltic birch plywood is a high-strength, aesthetically appealing form of plywood suitable for a wide range of applications. Contact Thomes to learn more about Baltic birch plywood and how it can help achieve the desired results in your next project.